| Number of control axes | 5 axes |

| Minimum programming | 0.001mm |

| Maximum programming | ± 99999.999mm |

| Top speed | 30m / min |

| Feed speed | 0.001-15m / min |

| Manual continuous | One axis or simultaneous multi-axis |

| Screen saver function | Screen saver function |

| Program editing | Male / English, relative / absolute programming |

| Pre-reading function | Short line preprocessing 10,000 lines |

| Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

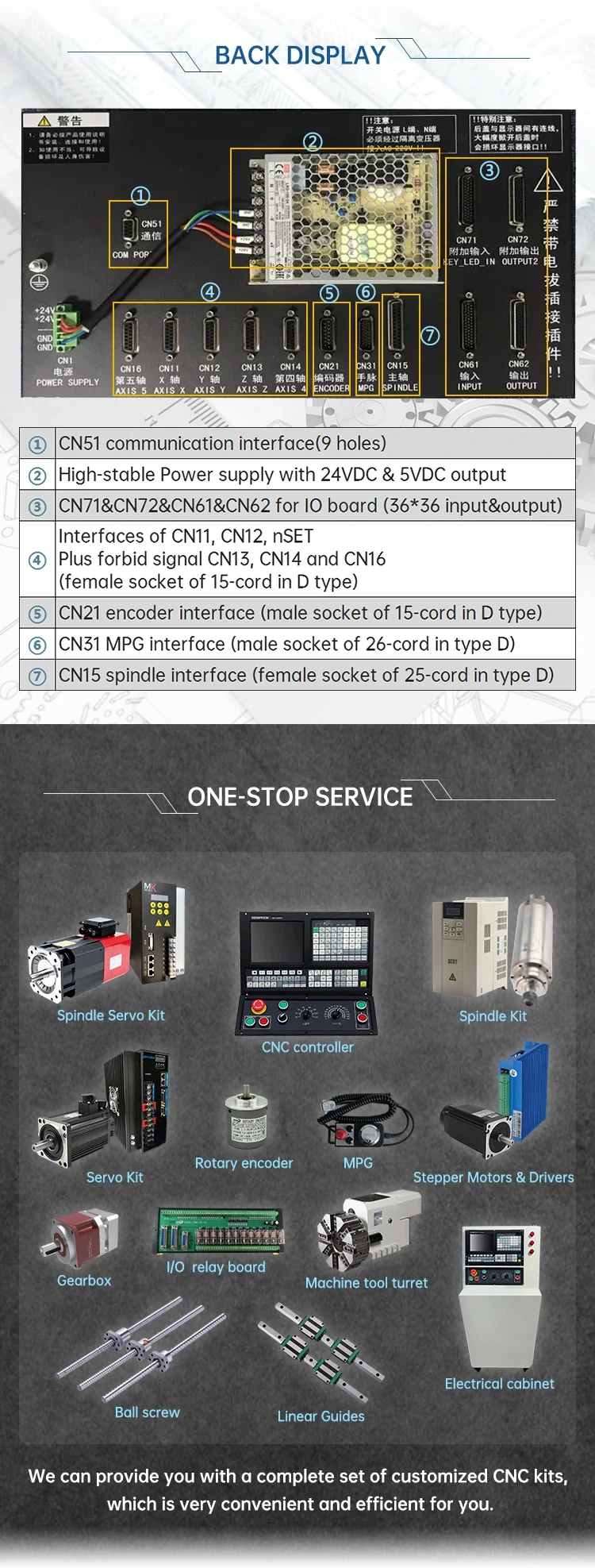

| Communication function | RS232, U disk interface |

| Program editing | Male / English, relative / absolute programming |

Tool functions: | 1)Tool length compensation |

| Program operation | Create, edit, delete, rename, search, copy, copy, paste, read in, out, background editing, dynamic graphics simulation |

| High-speed and high-precision machining | G05 high-speed small line segment look-ahead, trajectory smoothing processing, look-ahead and pre-reading up to 1000 segments |

Multiple function:

It can realize the drilling/boring,roughing of roungroove / rectanglegroove ,finishing of full circle /rectangle, continous drilling of straight line /rectangle /arc etc.

FAQ

Q1. Can I have a sample order for test?

A: Yes, we welcome sample order to test and check quality. We will provide the technical support. but if you does not have any basic knowledge,we do not suggest.

Q2. What about the lead time?

A: Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity.

Q3. How to proceed an order for our controller?

A: Firstly after you check our controller datasheet or you are familiar with the Mach3 controller,you can directly tell us how many axis you need or you can let us know your requirements or application and how many axis you need.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms and send the payment to us.

Fourthly We arrange the delivery.

If you have any questions, pls feel free to contact us. We'll be sure to get back to you within an hour on a business day.