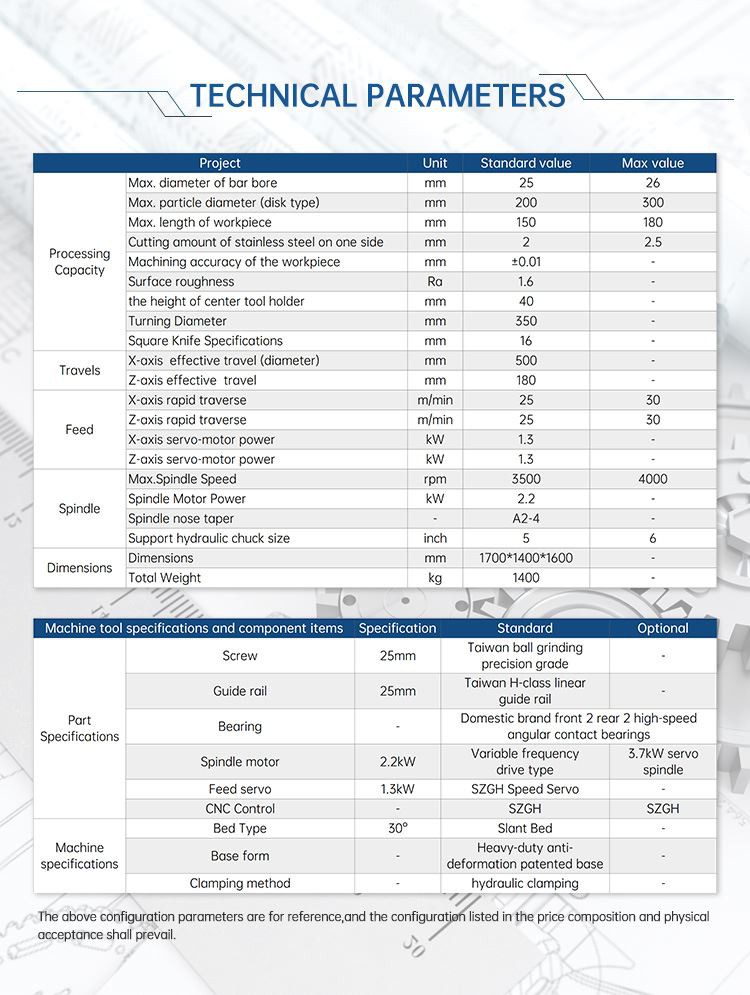

SZGH-25 CNC lathes machine are suitable for cutting copper, iron, aluminum and stainless steel bars within 25mm in diameter. The X-axis travel is 500mm and the Z-axis travel is 180mm. Using a number of patented technologies such as high rigidity and anti-deformation, it can easily achieve high-speed cutting of 2mm steel parts on one side. The machine tool weighs about 1.5 tons, has a machining accuracy of ±0.01mm, and supports flat bed and inclined bed structures. It can process straight lines, tapers, arcs, threads and other parts, and is especially suitable for bar processing below 25mm and mass production of post-process automated pellets. It can be equipped with a tool holder and various side and end power heads to form a simple turning and milling compound machine.

Spindle: Using angular contact high-speed bearings, the rated speed is 3500 rpm, which is suitable for large cutting volume processing. The clamping method can be changed from hydraulic to pneumatic clamping according to the customer's different use occasions. If there are high-speed and high-gloss requirements, a 6000-rpm high-speed electric spindle can be selected.

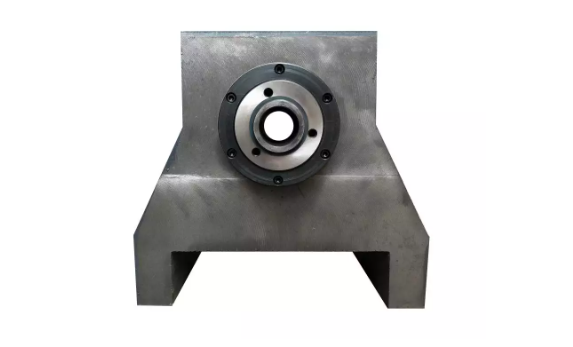

Rotating cylinder: The standard hydraulic rotating cylinder makes the clamping force larger, more stable and has a long service life. It can be replaced with pneumatic clamping according to actual conditions.

Screw: Use high-quality grinding-grade ball screw, which can be selected from Taiwan Shangyin or German Rexroth according to actual needs.

Guide rail: It adopts Taiwan Shangyin guide rail, and configurations of other brands can be selected according to actual needs.

It can be used with the tool holder to process long-axis workpieces.

CNC lathes machine It can be equipped with oil bath feeding, heavy hammer feeding and fully automatic loading rack device to achieve fully automated processing.